|

| September 06, 2022 | Volume 18 Issue 33 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

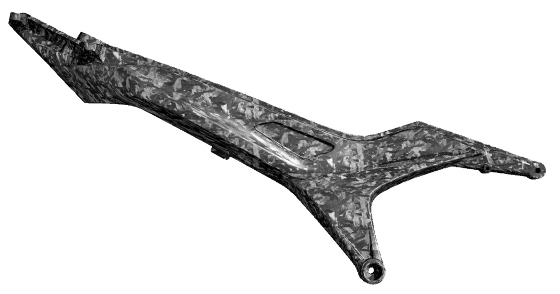

Composite replaces aluminum in new Ducati motorcycle seat frame

Mitsubishi Chemical Corp. recently showed off a key motorcycle part traditionally produced in metal that is now made of a unique carbon fiber composite. Developed as a joint research project with Gemini Composites (Seattle, WA) and high-end Italian cycle-maker Ducati, the new seat support rear frame saves 40% weight for the part and 3% on the overall weight of the motorcycle structure. The part was shown at the JEC World composites show in France this past May.

The seat support rear frame comprises the entire aft frame of the Ducati two-wheeler, forming an integral part of the chassis. It is designed based on fatigue strength criteria, but it also must meet stiffness, static strength, and finish requirements. The part developed replaces a cast aluminum component for the Ducati Hypermotard 939, a vehicle designed for both road and off-road racing, and constitutes the main structural support for the driver, optional passenger, and cargo bins.

The rear frame is made from MCC's Forged Molding Compound (FMC) material, an advanced version of Carbon Fiber Sheet Molding Compounds (CFSMC). Combined with a modified molding process and a dedicated design philosophy, the material is capable of yielding parts with properties suitable for primary structural applications.

According to MCC, "Carbon Fiber FMC is a special sheet-type intermediate material made of cut high-strength carbon fiber impregnated with thermosetting resin. This material can be press molded, substantially reducing molding time compared to conventional autoclave or oven molding.

"In addition, compared with carbon fiber intermediates of continuous fibers, the random arrangement of short fibers ensures fluidity and makes it possible to mold intricately shaped parts like those with ribs and bosses."

The material is suitable for complex shapes produced by press molding and can help to meet part lightweighting targets. It is already being used for mass-produced auto parts. Applications in sports is another key focus area.

The forged composite part weighs 0.8 kg (1.76 lb), while the aluminum one is 1.35 kg (2.98 lb) per side, which represents a total savings of 1.1 kg (2.43 lb), while maintaining the same cost and rate targets for the baseline aluminum component. The total motorcycle weight is 167 kg (388 lb).

"This technology enables Ducati to save 40% weight for the part and 3% on the overall weight of the motorcycle structure," said Dr. Di Piazza, head of Innovation and R&D Services at Ducati. "This yields lower fuel consumption and emissions, as well as higher handling and better dynamic response of the vehicle."

The design and analysis of the part was undertaken by Dr. Paolo Feraboli, chief technology officer, and Dr. Bonnie Wade, chief engineer, of Gemini in conjunction with Ducati, while the tool design and fabrication for the prototypes was performed by Claudio Chiara, owner principal of C.R.C. Model.

As part of the testing process, the motorcycle frame was installed on a mule frame and underwent static and cyclic testing at the Ducati R&D test lab with varying amounts of ballast to simulate the usage on the road. It successfully passed all durability requirements without degradation.

"We are convinced FMC will be a great option to replace structural parts which are commonly made by forged or cast aluminum to help reduce weight and increase mobility," said Koichi Akiyama, senior engineering manager at Mitsubishi.

Learn more at www.m-chemical.co.jp/carbon-fiber/en/product/fmc/.

Source: Mitsubishi Chemical Corporation

Published September 2022

Rate this article

View our terms of use and privacy policy